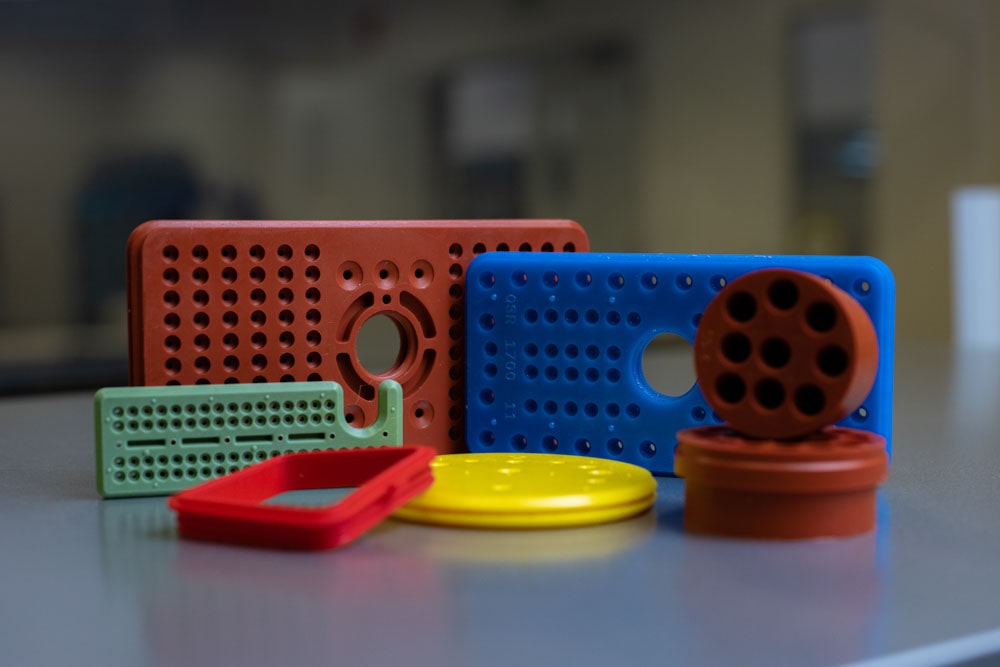

Manufacturing Technology for Intricate Components

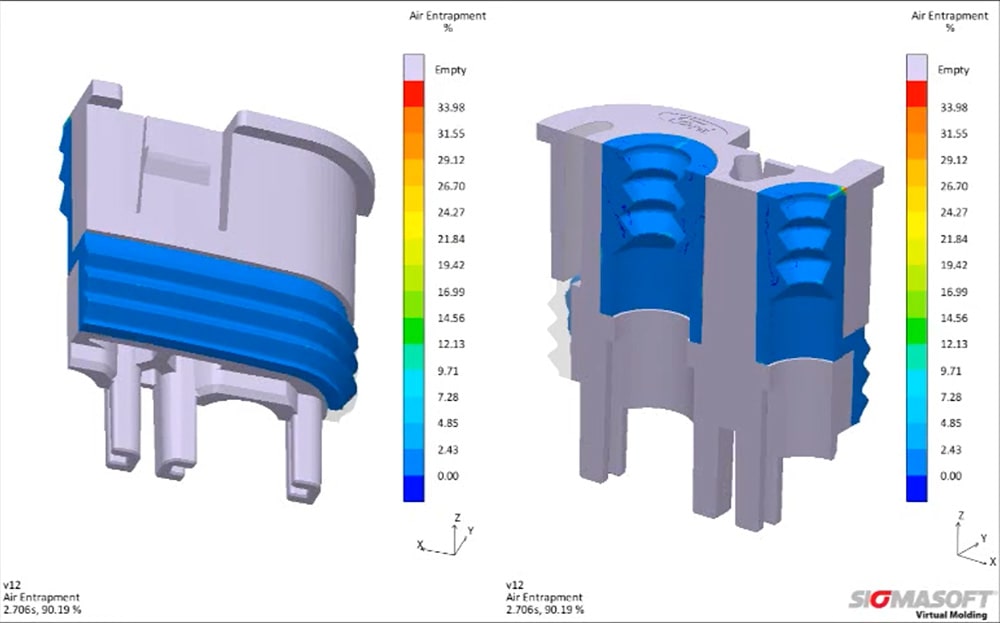

No matter the quantity, you can count on QSR to provide custom-molded silicone components of unsurpassed quality on time and within budget. QSR’s best-in-class Liquid Injection Molding, HCR and Overmolding manufacturing technologies are backed by extensive product engineering experience, vast material knowledge, in-house automation and tooling expertise along with the project management skills critical to keeping production on track.