When Precision Matters

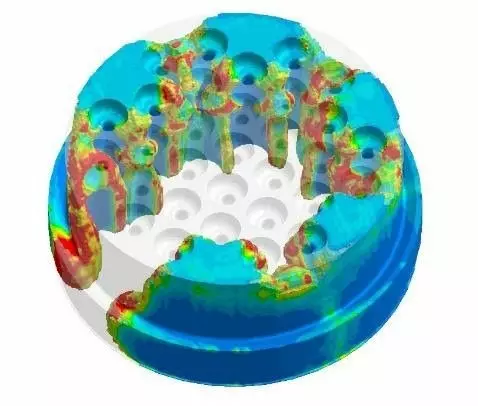

A global leader in Electrical Connector Sealing (ECS) and Ignition Insulating, QSR offers a diverse portfolio of mission-critical elastomeric solutions designed to safeguard electrical connections in even the toughest environments.

Decades of knowledge, along with world-class engineering and manufacturing capabilities in silicone and other rubbers, ensure your precision-molded components will perform and endure.

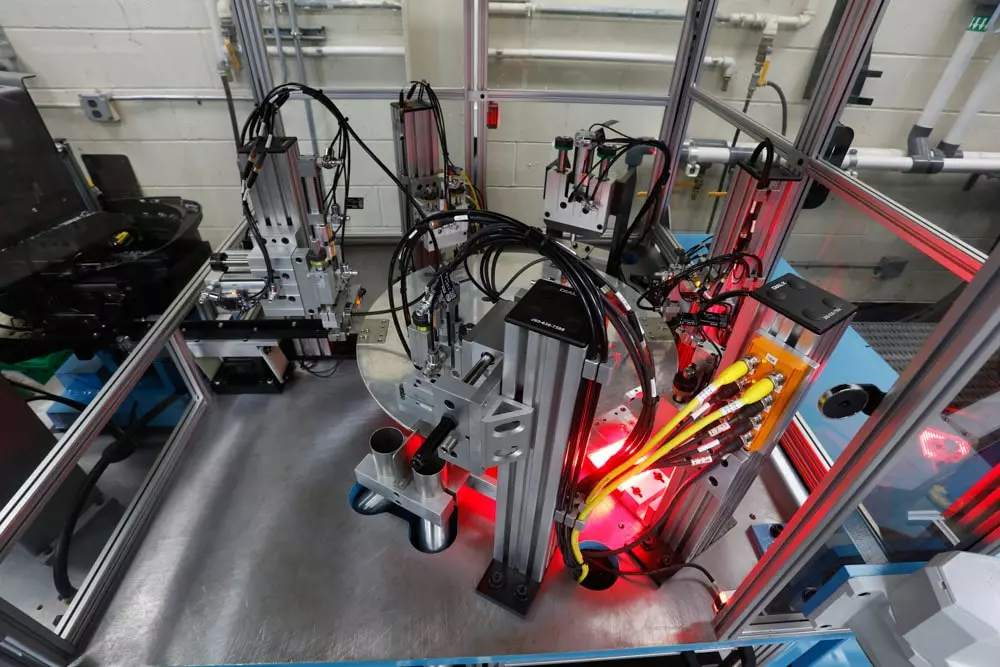

Unsurpassed Vertical Integration

Manufacturing and delivery of the best products on-time and within budget starts with engineer-to-engineer collaboration. QSR engineers partner with your team throughout the product lifecycle, providing turnkey design for manufacturability.